S02 Waterborne Basic Epoxy Micaceous Iron Oxide coating for metal surface Intermediate best selling

Product Description:

This epoxy micaceous iron oxide coating is a new generation of environmentally friendly anti-corrosion coating. It is prepared with waterborne two-component epoxy resin, amine curing agent, micaceous iron oxide, nano-functional materials, other anti-rust pigments, corrosion inhibitors and additives. It is a two-component epoxy intermediate coat with a ratio of component A to component B of 10:1.

This product is mainly used as the intermediate layer in the anti-corrosion system. It is located between the primer and the topcoat. The role of this intermediate paint is to enhance the anti-corrosion performance and adhesion of the entire coating system and meet the protection requirements of the entire coating. With water as the dispersion medium, no toxic or harmful substances are produced during the construction process and the coating film formation process.

Application use:

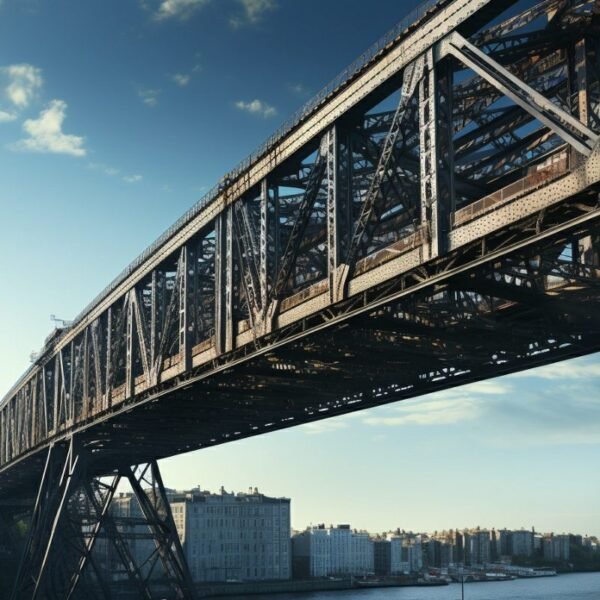

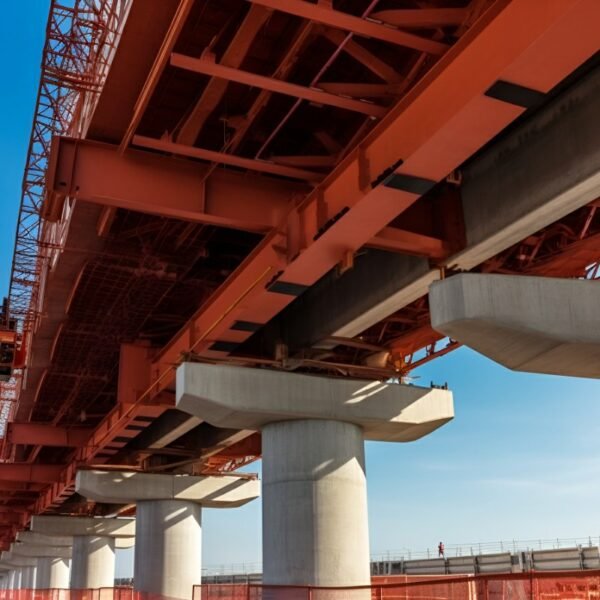

Suitable for various applications and substrates, including steel structure frames of large buildings such as stadiums, exhibition halls, bridges, etc., industrial steel structures such as factory building steel structures, pipelines, building supports, etc., and various industrial mechanical equipment such as machine tools, cranes, conveying equipment and other machinery.

Product performance parameters:

| Model | S02 | ||

| Gloss | Flat | ||

| Popular colors | Gray,Customized colors | ||

| Solids by volume | 42 ±2% | ||

| Density | 1.3 kg/l | ||

| Wet film thickness | 120-160 μm | ||

| Dry film thickness | 50-70 μm | ||

| Theoretical coating rate | 8.8-6.4 ㎡/l | ||

| Adhesion | Grade 0-1 | ||

| Impact resistance | 50 kg / cm | ||

| Drying time / Temperature | 15℃ | 25℃ | 35℃ |

| Surface dry (humidity 60%) | 1.5h | 1h | 30min |

| Hard dry (humidity 60%) | 8h | 6h | 4h |

Reviews

There are no reviews yet.