PC01 Waterborne Alkyd productive coating for oil tank and pipelines metal surface (Primer and Topcoat)

Product Description:

This Alkyd coating for oil tank and pipelines series is prepared with water-based alkyd functional resin and non-toxic and environmentally friendly anti-rust pigments, without adding organic solvents.

It has excellent anti-rust performance. With water as the dispersion medium, it meets environmental protection requirements. It has good adhesion and good compatibility, and has a high tolerance for substrates with incomplete rust removal. It is preferably used for long-term anti-corrosion applications such as refurbishing petroleum pipelines, pipelines and installations.

There are two models of products: primer and topcoat.

PC01 Primer Waterborne Alkyd coating for oil tank and pipelines metal surface Primer

PC01 Topcoat Waterborne Alkyd coating for oil tank and pipelines metal surface Topcoat

Application use:

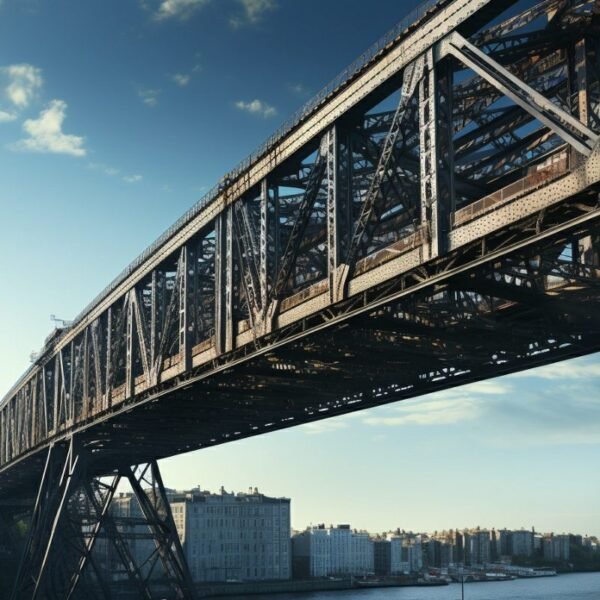

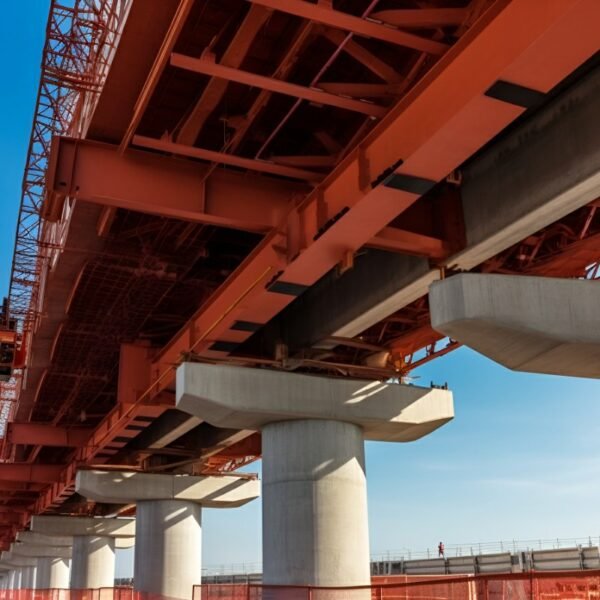

It is suitable for external anti-corrosion of various large steel structures, mechanical equipment, guardrail pipelines, cast iron parts, oil tanks, petrochemical oil pipelines and installations with harsh environments and high anti-corrosion performance requirements.

Product performance parameters:

| Model | PC01 Primer | PC01 Topcoat | ||||

| Gloss | Flat | High gross | ||||

| Popular colors | Iron Red,Gray,Customized colors | White,Gray,Bright Red,Peacock Blue,Customized colors | ||||

| Solids by volume | 42 ±2% | 40 ±2% | ||||

| Density | 1.3 kg/l | 1.2 kg/l | ||||

| Wet film thickness | 72-140 μm | 70-115 μm | ||||

| Dry film thickness | 30-60 μm | 28-46 μm | ||||

| Theoretical coating rate | 13.4-6.7 ㎡/l | 12.5-7.6 ㎡/l | ||||

| Adhesion | Grade 0-1 | Grade 0-1 | ||||

| Impact resistance | 50 kg / cm | 50 kg / cm | ||||

| Drying time / Temperature | 15℃ | 25℃ | 35℃ | 15℃ | 25℃ | 35℃ |

| Surface dry (humidity 60%) | 1.5h | 45min | 35min | 2h | 1h | 45min |

| Hard dry (humidity 60%) | 8h | 5h | 4h | 12h | 8h | 6h |

Reviews

There are no reviews yet.