One of the outstanding features of our products: NO complaints of “flash rusting” or “flash corrosion” on steel welding seams.

Traditional solvent paints contain large amounts of solvents, which are flammable and explosive, and cause serious environmental pollution. An increasing number of countries around the world are enacting various environmental policies to ensure sustainable development for humanity. Water-based paints are environmentally sustainable. However, during the construction process of water-based paints, a phenomenon known as “flash rusting” or “flash corrosion” can easily occur at steel welding seams.

Our KINA company’s water-based paints have not received any complains regarding such issues, which is one of our strong points and why we rank in the top 3 in the Chinese market for steel structure anti-rust and anti-corrosion water-based paints. Our products are highly favored by customers.

The following explanation is provided to everyone about what “flash rusting” or “flash corrosion” is.

“Flash rusting” or “flash corrosion” is an electrochemical phenomenon. Since the water in water-based paints is a conductor, it forms charge transfer in areas with potential differences. Under the combined action of water and oxygen, the contact between the water in the paint and the metal surface (especially at the steel welding seams) leads to corrosion.

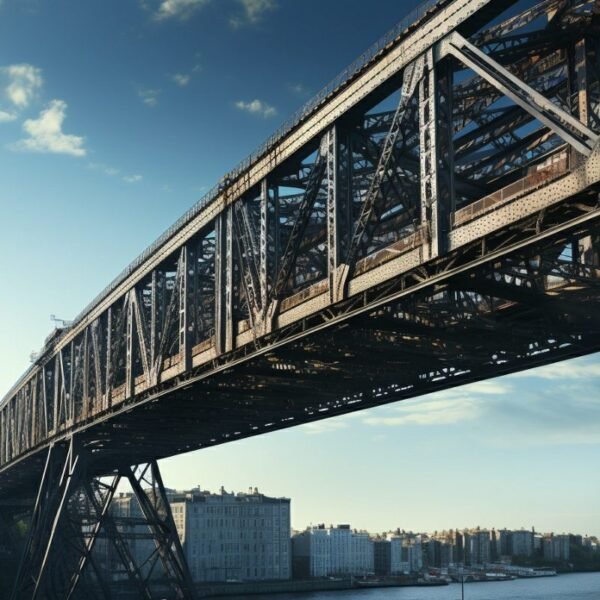

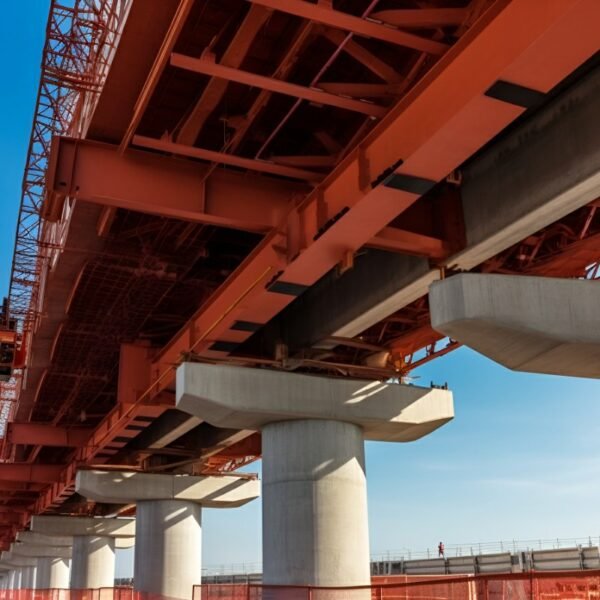

The following 3 pictures show the steel welding seams “flash rusting” or “flash corrosion” issues encountered by customers using OTHER brands.

No comment