FEEL FREE TO ASK US

FREQUENTLY ASKED QUESTIONS

"Welcome to our water-based coatings FAQ. As rust prevention and corrosion control experts, we share insights and engage in technical discussions.

Seek application tips, product knowledge, contact us by email,whatsapp,wechat, and receive accurate, timely responses here for corrosion-free surfaces."

- Quality

- Accuracy

- Safety

- Reliance

TECHNICAL QUESTIONS

Frequently asked questions

Discover the Future of Paints & Coatings: Eco-Friendly Water-Based Solutions by KINA!

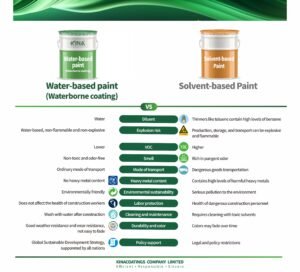

Revolutionizing the industry! Switch to water-based paints—the preferred choice over solvent-based alternatives. Why? Because your safety and the planet's health matter to us at KINA Coatings Company Limited. Our expertise lies in creating water-based coatings that embody efficiency, responsibility, and sincerity in every drop.

🌟 Safe & Non-Toxic: Unlike solvent-based paints that use hazardous thinners like toluene, packed with dangerous benzene, our water-based paints use... you guessed it—water! No flammability, no explosions, just peace of mind during production, storage, and transport.

🌿 Low VOC Emissions: Join the green revolution. We're aligned with global sustainability goals, emitting fewer Volatile Organic Compounds compared to conventional paints. Say goodbye to harmful pollutants and hello to fresher air.

🛡️ Heavy Metal-Free: Our paints don't hide toxic secrets. Free from heavy metals, unlike solvent-based competitors, ensuring the safety of humans and Mother Nature alike.

👷♂️ Healthier Workspaces: Workers rejoice! Water-based paints mean no toxic fumes, no impact on health. Enjoy an odorless painting experience—a breath of fresh air for construction sites everywhere.

💦 Easy Cleanup: After painting, cleanup becomes a breeze. Just add water, not harsh chemicals. Solvent-based paints require toxic solvents, but not our water-based wonders!

☀️ Weatherproof & Durable: Performance doesn't compromise sustainability. Our paints withstand the elements, resisting wear and tear while keeping their vibrant colors intact. Quality that lasts and looks good doing it.

💚 Green Choice, Brighter Future: Your choice matters. Opting for water-based paints isn't just about preference; it's a commitment to worker welfare and environmental conservation. Embrace the eco-movement sweeping the globe, where the advantages of water-based paints shine brighter than ever.

At KINA Coatings Company Limited, we're leading the charge, delivering water-based coatings that represent more than just an option—it's your stride toward a greener tomorrow. Make the switch today and join us in painting a healthier world!

Unleashing the Power of Water-Based Acrylic Anti-Corrosive & Rust-Proof Paints: Your Ultimate Protective Shield

In the vast and ever-evolving landscape of protective coatings, water-based acrylic paints have emerged as a game-changer, particularly when it comes to combating corrosion and rust. Let's dive into the fascinating world of these coatings, revealing how they safeguard your assets with an eco-friendly, high-performance barrier.

What is Water-Based Acrylic Anti-Corrosive & Rust-Proof Paint?

A water-based acrylic anti-corrosive and rust-proof paint is a specialized, eco-friendly coating designed to shield surfaces from the relentless attack of environmental elements. Unlike traditional solvent-based paints that rely on volatile organic compounds, water-based acrylic paints utilize water as the primary solvent, significantly reducing harmful emissions.

Key Benefits & Unmatched Performance

Non-Toxic & Odorless: Enjoy a safer painting experience with no toxic fumes or unpleasant odors, making it ideal for indoor and outdoor use alike.

Eco-Friendly: Low VOC emissions mean a lower impact on the environment, aligning with sustainable practices and regulations.

Easy Application & Cleanup: Water-based paints offer smooth application and clean up with water, eliminating the need for harsh solvents.

Excellent Adhesion: Superior adhesion to a variety of surfaces ensures a lasting and protective coating.

Weather & UV Resistance: These paints withstand harsh weather conditions and resist UV degradation, maintaining their color and integrity over time.

Corrosion & Rust Protection: A robust barrier against corrosion and rust, safeguarding metal surfaces and prolonging their life.

Why Choose Water-Based Acrylic for Anti-Corrosive Needs?

In an era where environmental consciousness and health concerns are paramount, water-based acrylic anti-corrosive and rust-proof paints offer a superior, safer alternative. They not only deliver unmatched protection against corrosion and rust but do so with a lower environmental footprint. Their versatility and performance make them a preferred choice for a wide range of applications, from industrial machinery to household items, ensuring your investments remain protected and looking their best for years to come.

Empowering Protection: The Science Behind Water-Based Alkyd Anti-Corrosive & Rust-Proof Paints

In the realm of protective coatings, the evolution towards more sustainable and efficient materials has led to the prominence of water-based alkyd paints. These coatings, particularly designed to combat corrosion and prevent rust, have become a cornerstone in various industries. Let's unravel the essence of water-based alkyd anti-corrosive and rust-proof paints, highlighting their benefits and performance.

Decoding Water-Based Alkyd Coatings

Water-based alkyd anti-corrosive and rust-proof paints are advanced formulations that utilize water as the primary solvent, replacing traditional organic solvents. This shift not only reduces the environmental impact but also enhances user safety. These paints are specifically engineered to shield surfaces from the damaging effects of corrosion and rust, offering a reliable and eco-friendly protective layer.

The Edge of Water-Based Alkyd Paints

Safety & Health: With minimal volatile organic compounds (VOCs), water-based alkyd paints offer a safer painting experience, free from toxic fumes, making them ideal for use in both residential and commercial spaces.

Eco-conscious Choice: Reduced VOC emissions align with global efforts to minimize environmental pollution, making these paints a sustainable choice for conscientious consumers and industries.

Ease of Use: These paints provide a smooth, easy application process, and cleanup is a breeze with water, eliminating the need for harsh chemical solvents.

Adaptive Adhesion: Water-based alkyd paints are known for their superior adhesion, providing a durable and lasting bond to a variety of surfaces, including metal, wood, and concrete.

Corrosion & Rust Defense: Formulated with advanced corrosion inhibitors, these paints create a resilient barrier against moisture, salt, and other corrosive elements, effectively preventing rust formation.

Weather Resistance: They stand strong against environmental challenges, including UV rays and extreme temperatures, ensuring that the surface remains protected and retains its aesthetic appeal.

Why Water-Based Alkyd for Anti-Corrosive Applications?

Choosing water-based alkyd anti-corrosive and rust-proof paints is not just about meeting regulatory standards or environmental goals; it's about investing in a protective solution that delivers superior performance. These coatings not only shield assets from the ravages of corrosion and rust but also do so with a lower environmental footprint, showcasing the perfect marriage of sustainability and resilience. Whether for industrial applications, marine environments, or everyday household needs, water-based alkyd paints offer a protective shield that stands the test of time.

Diving into Water-Based Epoxy: The Ultimate Anti-Corrosive and Rust-Proof Coating Solution

In the quest for advanced protective coatings, water-based epoxy resins have emerged as a leading solution in the battle against corrosion and rust. Offering a potent combination of durability, safety, and environmental consciousness, these coatings redefine the standards of surface protection. Let's explore the essence of water-based epoxy resin anti-corrosive and rust-proof paints, their advantages, and why they are a top choice for various industries.

Understanding Water-Based Epoxy Resin Paints

Water-based epoxy resin paints are innovative coatings formulated with water as the primary solvent, replacing harmful organic solvents. Designed to combat corrosion and inhibit rust formation, these paints create a robust barrier for surfaces exposed to harsh environments. Their unique formulation enhances their performance while prioritizing user safety and environmental health.

The Superiority of Water-Based Epoxy Resins

Safety & Health: With significantly lower volatile organic compounds (VOCs), water-based epoxy paints offer a safer painting experience, free from toxic fumes. This makes them suitable for indoor and confined spaces, ensuring the well-being of workers and inhabitants.

Eco-friendly Choice: Reduced VOC emissions align with global sustainability efforts, making these paints an environmentally conscious choice. They contribute to cleaner air and reduced pollution, meeting stringent environmental regulations.

Versatility & Application: Water-based epoxy resins offer easy application, with the added convenience of water-based cleanup, eliminating the need for toxic solvents. They are adaptable to various surfaces, providing a seamless protective layer.

Corrosion & Rust Resistance: These paints are formulated to resist corrosion, effectively shielding surfaces against moisture, chemicals, and extreme conditions that lead to rust formation. Their barrier properties are unmatched in the realm of protective coatings.

Durable & Long-Lasting: Water-based epoxy coatings are known for their longevity and resilience. They maintain their integrity over time, withstanding wear and tear, and preserving the surface's aesthetic and structural integrity.

Adhesion & Flexibility: They exhibit superior adhesion, ensuring a strong bond to various substrates, including metal, concrete, and wood. The flexibility of these coatings accommodates surface movement without cracking or peeling.

Why Water-Based Epoxy for Anti-Corrosive Applications?

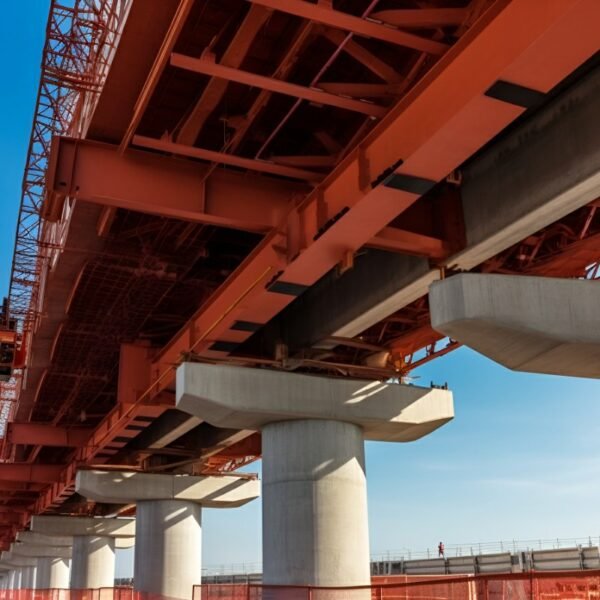

When it comes to protecting your investments from corrosion and rust, water-based epoxy resin paints offer an unparalleled solution. They not only safeguard surfaces against harsh environmental conditions but do so with a reduced impact on human health and the environment. Whether for marine environments, industrial machinery, or critical infrastructure, water-based epoxy coatings provide a sustainable, durable, and high-performance protective layer.

Pioneering Protection: The Role of Water-Based Epoxy Zinc-Rich Anti-Corrosive & Rust-Proof Paints

Within the domain of high-performance protective coatings, water-based epoxy zinc-rich paints have carved out a niche as the vanguard against corrosion and rust. Combining the strength of epoxy with the protective qualities of zinc, these coatings offer a powerful defense mechanism for surfaces vulnerable to environmental stresses. Let's delve deeper into what sets water-based epoxy zinc-rich paints apart and why they are indispensable in various sectors.

The Science Behind Water-Based Epoxy Zinc-Rich Coatings

Water-based epoxy zinc-rich paints are specialized formulas that harness the protective properties of zinc particles suspended in an epoxy matrix, utilizing water as the solvent. This innovative composition ensures a low-VOC emission profile, enhanced safety measures, and improved environmental compatibility—all while fortifying surfaces against corrosion and rust.

Exploring the Advantages of Water-Based Epoxy Zinc-Rich Paints

Health & Safety: With minimized volatile organic compounds (VOCs), these paints ensure a safer working environment. The lack of toxic fumes is especially beneficial for indoor projects and areas with limited ventilation.

Environmental Stewardship: Lower VOC content translates into reduced environmental impact, meeting strict ecological guidelines and promoting green practices across multiple industries.

Application Ease: Water-based cleanup simplifies the process, saving time and resources typically spent on harsh chemical solvents. The paints' viscosity allows for easy application through brushing, rolling, or spraying techniques.

Superior Corrosion & Rust Protection: Zinc particles act as sacrificial anodes, inhibiting corrosion through cathodic protection. Coupled with the epoxy matrix's impermeability, this creates a formidable barrier against moisture intrusion and subsequent rust formation.

Durability & Longevity: Once cured, water-based epoxy zinc-rich coatings form a hard, abrasion-resistant film. This extended lifespan minimizes maintenance costs and extends asset service life.

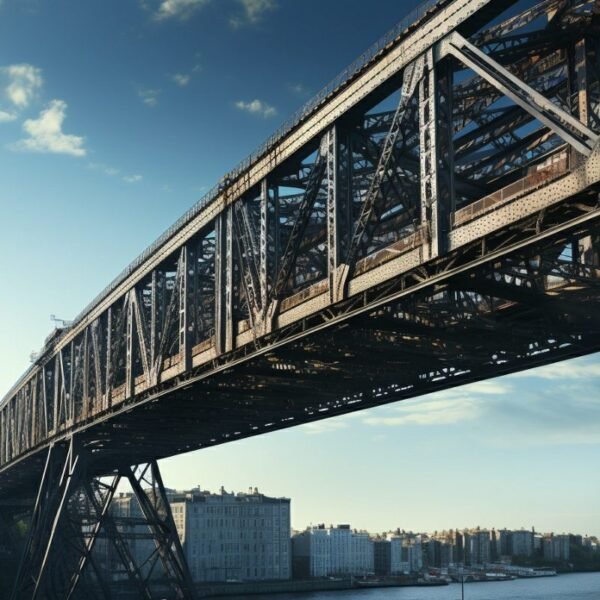

Multi-Surface Compatibility: Whether applied to steel structures, bridges, or offshore platforms, these paints adhere well to metallic surfaces, ensuring comprehensive coverage and protection.

Selecting Water-Based Epoxy Zinc-Rich for Critical Coating Needs

For industries seeking a robust, eco-conscious solution to counteract corrosion and rust effectively, water-based epoxy zinc-rich paints emerge as a clear frontrunner. These coatings encapsulate the essence of innovation, merging the best attributes of epoxy polymers and zinc chemistry to protect valuable assets in hostile environments. Their widespread adoption signifies a step forward in sustainable protection methods that prioritize both performance and environmental stewardship.

Unlocking Durability: An Exploration of Water-Based Polyurethane Zinc Anti-Corrosive & Rust-Proof Paints

In the dynamic field of protective coatings, water-based polyurethane zinc paints have taken center stage as a premier solution against corrosion and rust. Blending the toughness of polyurethane with the sacrificial protection of zinc, these coatings redefine the standards of surface preservation. Let's uncover the science behind water-based polyurethane zinc paints, their benefits, and why they are essential for various industries.

The Core of Water-Based Polyurethane Zinc Coatings

Water-based polyurethane zinc paints integrate the robustness of polyurethane binders with the protective prowess of zinc particles, employing water as the dispersant. This approach leads to a high-performance coating that is safe, eco-friendly, and highly effective in shielding surfaces against environmental damage.

Benefits of Water-Based Polyurethane Zinc Paints

Enhanced Environmental Responsibility: With decreased levels of volatile organic compounds (VOCs), these paints offer a safer alternative, contributing positively to air quality and complying with stringent environmental laws.

User Safety First: Reduced toxicity means a better work environment, minimizing risks associated with inhalation of harmful fumes, particularly advantageous for interior applications and enclosed spaces.

Seamless Application Process: Water as a cleaning agent simplifies the painting process, reducing waste and increasing efficiency. Its ease of handling appeals to both professional painters and DIY enthusiasts alike.

Ultimate Corrosion Barrier: Zinc components act as sacrificial barriers, offering superior corrosion resistance. Combined with the inherent water-resistance of polyurethane, these paints create a formidable shield against moisture and rust.

Long-Term Durability: Known for their tough finish, water-based polyurethane zinc paints endure extreme conditions and wear, ensuring long-lasting protection and reducing maintenance frequency and costs.

Broad Surface Compatibility: Whether used on industrial equipment, maritime vessels, or architectural structures, these paints adapt easily to diverse substrates, delivering uniform protection and aesthetics.

Embracing Water-Based Polyurethane Zinc for Enhanced Protection

For organizations aiming to enhance the lifespan of their assets while committing to responsible environmental practices, water-based polyurethane zinc paints present an optimal choice. Their blend of durability, safety, and sustainability positions them as the ultimate ally in the fight against corrosion and rust. Adopting these coatings not only safeguards valuable investments but also demonstrates a proactive stance toward preserving the environment.

Defying the Elements: The Protective Power of Water-Based Asphalt Anti-Corrosive & Rust-Proof Paints

In the realm of industrial coatings, water-based asphalt paints stand out as a robust solution for corrosion and rust prevention. This innovative approach merges the time-tested durability of asphalt with the eco-friendliness and safety of water-based formulations. Let's unravel the science and benefits of water-based asphalt anti-corrosive and rust-proof paints, underscoring their significance in various applications.

The Essence of Water-Based Asphalt Coatings

Water-based asphalt paints are specialized coatings that leverage the protective qualities of asphalt and the environmental sensibility of water as a solvent. This combination results in a coating that is both tough and eco-friendly, providing a reliable shield against environmental damage.

Key Advantages of Water-Based Asphalt Paints

Eco-Friendly Formulation: With significantly reduced volatile organic compounds (VOCs), these paints offer a safer alternative for the environment and human health. They align with stringent environmental regulations, promoting sustainable practices.

Simplified Application & Cleanup: Water serves as both the solvent and cleaning agent, simplifying the painting process. This ease of use makes them accessible for professionals and DIY enthusiasts alike.

Weather Resistance: Water-based asphalt paints are designed to withstand harsh weather conditions, including UV exposure, moisture, and extreme temperatures. Their resilience ensures long-lasting protection for surfaces.

Corrosion & Rust Prevention: The asphalt component acts as a barrier, effectively preventing corrosion and rust from penetrating the surface. This protective layer is crucial for assets exposed to corrosive environments.

Cost-Effective Durability: These paints offer a cost-effective solution for long-term surface preservation. Their durability reduces maintenance needs, saving on both time and resources.

Versatility & Adhesion: Suitable for a variety of surfaces, including metal, concrete, and masonry, water-based asphalt paints provide a strong bond, ensuring comprehensive coverage and protection.

Choosing Water-Based Asphalt for Enhanced Protection

Water-based asphalt anti-corrosive and rust-proof paints offer a practical and sustainable solution for safeguarding assets against the ravages of corrosion and rust. Their blend of durability, environmental friendliness, and ease of use makes them an ideal choice for a wide range of applications, from infrastructure to industrial machinery. Embracing these coatings not only fortifies your assets but also demonstrates a commitment to responsible environmental practices.

Elevating Finish Standards: The Impact of Water-Based Alkyd Enamel Paints

In the ever-evolving landscape of paint coatings, water-based alkyd enamel, commonly referred to as water-based amino baking paint, has disrupted traditional norms. Bridging the gap between performance and environmental responsibility, this type of paint offers a new benchmark for finishing processes. Let’s dissect its core characteristics and benefits, illuminating why water-based alkyd enamels have become indispensable in various industries.

Decoding Water-Based Alkyd Enamel Paints

Water-based alkyd enamels are a novel class of coatings that utilize water as the primary carrier instead of oil or solvent. This shift towards aqueous media significantly alters the paint’s environmental footprint, making it much more eco-friendly without compromising on durability or finish quality.

Advantages That Define Water-Based Alkyd Enamels

Reduced Environmental Impact: Low volatile organic compounds (VOCs) make water-based alkyd enamels a greener option, adhering to strict environmental regulations and promoting sustainable practices.

Ease of Application & Cleanup: Utilization of water as a thinner streamlines the painting process and simplifies clean-up procedures, enhancing productivity for both professionals and DIY enthusiasts.

Rapid Drying Time: Despite being water-based, these enamels boast quick drying times akin to solvent-based counterparts, enabling faster turnaround and increased operational efficiency.

Robust Finish Quality: Water-based alkyd enamels deliver a hard-wearing and glossy finish similar to their solvent-based versions, ensuring surfaces remain aesthetically pleasing and protected.

Chemical & Abrasion Resistance: These paints exhibit commendable resistance against chemicals, staining agents, and mechanical stress, making them suitable for industrial settings where durability is paramount.

Wider Application Scope: From automotive refinishing to furniture manufacturing, water-based alkyd enamels find versatile uses due to their ability to adhere to various substrates, including metals, woods, and plastics.

The Future of Coatings with Water-Based Alkyd Enamels

As industries increasingly prioritize sustainable solutions without sacrificing product performance, water-based alkyd enamels represent a progressive choice. By integrating these paints into manufacturing and maintenance routines, companies can reduce their carbon footprint while maintaining high-quality finishes, setting a precedent for others to follow.

Reinventing Resilience: Exploring Solvent-Free Flooring Paints

In the domain of floor coating innovations, solvent-free flooring paints have emerged as a beacon of progress, combining performance excellence with environmental consciousness. Designed to eliminate volatile organic compounds (VOCs), these paints redefine the boundaries of commercial and residential flooring. Here, we demystify the essence of solvent-free flooring paints and highlight their compelling advantages.

Understanding Solvent-Free Flooring Paints

Solvent-free paints, a pioneering advancement in the coating industry, are engineered to omit solvents traditionally used in paint formulation. Instead, these coatings rely on resins that cure via chemical reactions when mixed with activators or upon exposure to ambient conditions, thus achieving a solid film without the need for volatile carriers.

Core Benefits of Solvent-Free Flooring Paints

Eco-Friendly Profile: Devoid of solvents, these paints significantly lower their environmental impact, aligning with green building initiatives and regulatory requirements aimed at minimizing pollution.

Safety & Health Assurance: The absence of harmful fumes during application and curing phases enhances safety for workers and inhabitants, contributing to healthier living and working environments.

Increased Productivity: With no need for lengthy airing periods post-application, solvent-free flooring paints expedite project completion, allowing for quicker return-to-service intervals.

Optimal Surface Performance: Offering superior adhesion properties and chemical resistance, these paints create a durable, seamless finish capable of enduring heavy foot traffic and industrial wear.

Extended Coating Life: Resistant to cracking and peeling, solvent-free flooring paints maintain their integrity over time, reducing maintenance costs and downtime for recoating.

Flexibility in Application: Suitable for a broad spectrum of surfaces, from concrete floors to metal decks, these paints cater to diverse flooring requirements, ensuring lasting protection and aesthetic appeal.

Adopting Solvent-Free Flooring Paints for Sustainable Solutions

By embracing solvent-free flooring paints, businesses and homeowners can enjoy the dual benefits of advanced performance and reduced environmental impact. As global trends gravitate towards sustainable practices, these innovative coatings set the standard for next-generation flooring solutions, promising resilience, safety, and ecological harmony.

GENERAL QUESTIONS

Frequently asked questions

Navigating Safer Shipment Routes: Our Commitment to Waterborne Paints

Pioneering the transition from traditional solvent-borne paints to waterborne alternatives, our company stands at the forefront of environmentally conscious and safety-driven coating solutions. Unlike conventional paints laden with toxic solvents, our waterborne paints are classified non-hazardous, opening up convenient shipping avenues that include courier services, land transportation, and ocean freight.

The Distinction of Non-Hazardous Shipments

Our commitment to producing waterborne paints goes beyond mere compliance; it embodies a pledge to safety and environmental stewardship. By harnessing the power of water as the primary solvent, we ensure that our products not only meet stringent safety standards but also significantly mitigate environmental impacts typically associated with volatile organic compounds (VOCs).

Effortless Logistics: Courier Services & Beyond

Recognized as non-dangerous goods by shipping authorities, our waterborne paints effortlessly navigate through courier networks. Whether it's urgent shipments across town or international deliveries, customers benefit from swift delivery timelines and peace of mind knowing their orders are handled with minimal regulatory hurdles.

Land Freight: Streamlined Transportation Options

With an absence of flammable substances, our paint products are perfect candidates for land transport methods, including trucks and railway cargo. This versatility enables us to offer flexible delivery schedules that accommodate bulk orders and large-scale projects without the constraints often faced with hazardous materials.

Seaborne Expeditions: Far-reaching Distribution

Expanding our reach globally, our waterborne paints embark on seafaring journeys without impediments posed by hazardous material classifications. By leveraging sea routes, we facilitate access to distant markets, ensuring that our commitment to safety and sustainability transcends borders.

Documentation Excellence: MSDS & Shipping Certifications

To uphold transparency and facilitate smooth logistics operations, we furnish Material Safety Data Sheets (MSDS) alongside shipping certifications for both air and sea transports. These documents affirm our dedication to safety protocols and reassure clients of adherence to international shipping guidelines.

Charting a Greener Course Together

By choosing our waterborne paints, customers not only gain access to a superior coating experience but also contribute to a future defined by sustainability and safety. Together, let us advance the paint industry toward more conscientious and efficient shipment practices, paving the way for broader adoption of non-hazardous materials worldwide.

Mastering Rust Resistance: Specializing in Waterborne Industrial Anti-Corrosive Coatings

At the vanguard of industrial protective coatings, our focus lies on waterborne rust preventive and anti-corrosive paints—innovative solutions that redefine industry standards. We pride ourselves on a production timeline that ensures swift delivery without compromising on quality, typically spanning a mere 3-7 working days from order confirmation.

Our Niche in Waterborne Coatings

Dedication to waterborne technology has allowed us to craft paints that not only excel in corrosion resistance but also stand out for their environmental friendliness. By harnessing the power of water as a solvent, our coatings offer a safer, greener alternative to traditional solvent-borne products, aligning with the industry's shift towards sustainability.

Swift Production & Delivery

Understanding the critical nature of industrial operations, we have optimized our production processes to meet tight timelines without sacrificing product integrity. This 3-7 day production window ensures that our clients receive their bespoke coatings in a timeframe that aligns with their project schedules, minimizing delays and maximizing efficiency.

Custom Solutions & Quality Assurance

Every order is treated with the utmost care, undergoing rigorous quality checks throughout the production process. From formulation to packaging, our team ensures that each batch meets our stringent standards, delivering paints that are both effective and reliable in the field.

Simplifying Your Logistics

Our streamlined production schedule not only guarantees prompt delivery but also allows for easier planning on your end. Whether you're managing a large-scale infrastructure project or a series of smaller maintenance needs, our quick turnaround ensures that you have the coatings you require when you need them.

Partnering for Protection

Choose us as your preferred supplier for waterborne industrial anti-corrosive coatings, and experience the blend of expertise, efficiency, and environmental consciousness. Together, we can protect your assets from the elements while contributing to a more sustainable future.

Tailored Solutions: Our Range of Waterborne Paint Packaging Sizes

Embracing versatility in our approach to customer satisfaction, we proudly offer waterborne paints packaged in various sizes to suit every need—from small home renovation projects to expansive commercial endeavors. Our carefully curated lineup includes 10L, 15L, 18L, 20L, 50L, 100L, and even 200L containers, ensuring there's a fit for any scale of work.

Catering to All Scales of Projects

Acknowledging that every client's requirement is unique, we've designed our packaging options with flexibility in mind. The compact 10L to 20L range caters to individual users seeking precise quantities for personal spaces, offering convenience and minimized waste. For larger-scale applications, such as industrial facilities or extensive construction sites, our expansive 50L, 100L, and 200L volumes provide substantial capacity, optimizing efficiency and cost-effectiveness.

Commitment to Quality & Sustainability

Regardless of size, each container is filled with our premium waterborne涂料, formulated for superior performance and environmental friendliness. Our commitment extends beyond the product itself, incorporating responsible packaging choices that reflect our dedication to sustainability.

Streamlined Selection for Seamless Projects

Whether you're a homeowner tackling a weekend refresh, a contractor overseeing multiple job sites, or a facility manager requiring bulk supplies, our comprehensive packaging selection ensures a hassle-free ordering process. Choose the volume that best aligns with your project scope, secure in the knowledge that each drop contains our unwavering quality promise.

Your Trusted Partner in Waterborne Paint Solutions

From the precision of smaller packages to the robustness of larger drums, we stand ready to support your painting endeavors with our wide range of waterborne paint packaging sizes. Select what suits you best, and together, let's bring your vision to life with sustainable, high-performance coatings.

Ask Us

Quick contact form